Hience-U series

As a graphene planar heating unit coated with Al, it has an excellent temperature uniformity and a large heating area, so it is advantageous to maintain efficiency compared to a conventional coil heater.

Since the heat source itself is a film type, it has a structural advantage that can be thinned structurally, and is not greatly limited by its shape.

Lighter and more durable than conventional heaters.

In actual use, it is more resistant to thermal shock than conventional ceramic heaters.

Because of no oxidation, there is little damage to the heater and a long life.

In the case of conventional carbon heaters or graphene heaters, a binder was used, which made heating at high temperatures difficult.

However, our planar heating devices generate heat of over 400℃ through a binder developed with know-how.

It is an efficient heating element manufactured and produced in various shapes and sizes and consumes only 1/3 of the power consumption compared to the existing power consumption.

Characteristics

Unit frame : Aluminum

Board area (mm) : Various

Heating Area (mm) : Various

Shape : Plate/Industrial DIY

Recommended for use

Heating machine

Heater/warmer, Dryer

Industrial PTC heater

Electric vehicle heater

Industrial boiler, Air/Water

heater, Large dryer, Warm

air blower/Injection/Molding

machine, Heating bonding

equipment, etc.

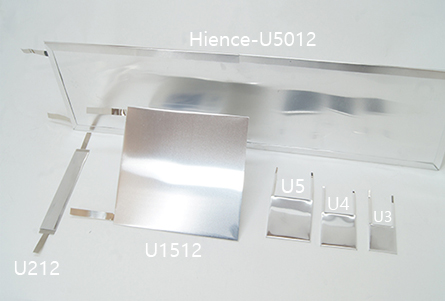

| Unit Name | Size(mm) |

Heating Area(mm) |

Shape | Vol (V) |

Power (W) |

Temp (℃) |

|---|---|---|---|---|---|---|

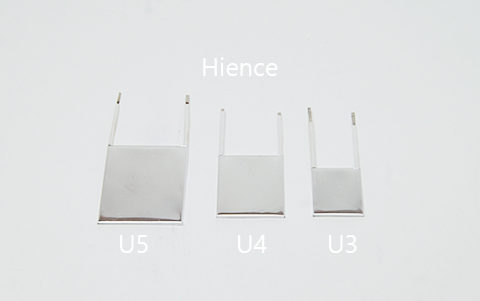

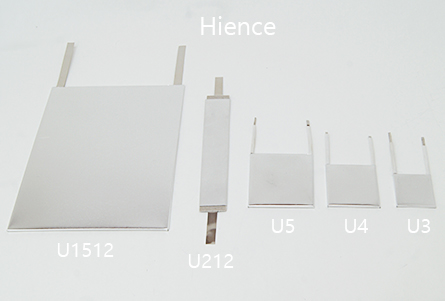

| Hience-U3 | 30 x 30 x 1.5(t) |

30 x 30 x 1.5(t) | Plate | 9 |

21 |

400 |

| Hience-U4 | 40 x 40 x 1.5(t) |

40 x 40 x 1.5(t) | Plate | 12.5 |

31 |

400 |

| Hience-U5 | 50 x 50 x 1.5(t) |

50 x 50 x 1.5(t) | Plate | 17 |

47 |

400 |

| Hience-U212 | 20 x 120 x 1.5(t) |

20 x 120 x 1.5(t) | Plate | 30 |

38 |

400 |

| Hience-U1512 | 150 x 120.5 x 2(t) |

150 x 120.5 x 2(t) |

Industrial DIY | 210 |

265 |

400 |

| Hience-U5012 | 500 x 120.5 x 2(t) |

500 x 120.5 x 2(t) | Industrial DIY | 210 |

800 |

400 |