Technology

The products of UDCORE, UD's own brand, are composed of technology-based products.

Flexible, thin-film plate-type heating elements, and block heater modules are produced with our own technology.

In addition, we have technology for producing materials for sensors and graphene metal alloy technology.

We produce graphene and pure aluminum castings.

Energy efficiency up to 300% Core complexes with excellent properties!

We are UD Co., Ltd.

that produces energy materials that are meaningful to nature and people.

Materials for Electric

UD's graphene metal oxide composite is developed for applying to electronic devices.

Among them, the graphene-SnO2 composite has excellent performance in sensors for detecting atmospheric NO2.

In general, SnO2 is all thing of the sensor material for NO2 gas sensor, Our products have graphene functionalized structure on the SnO2-Sn: core-shell structure so composite that has changed the work function and the band gap of SnO2.

This structural design allows the sensor to operate at room temperature, although the existing sensor operating temperature was over 200℃.

At the same time, electrical barriers between grain boundaries are reduced to reduce electrical signal noise or loss.

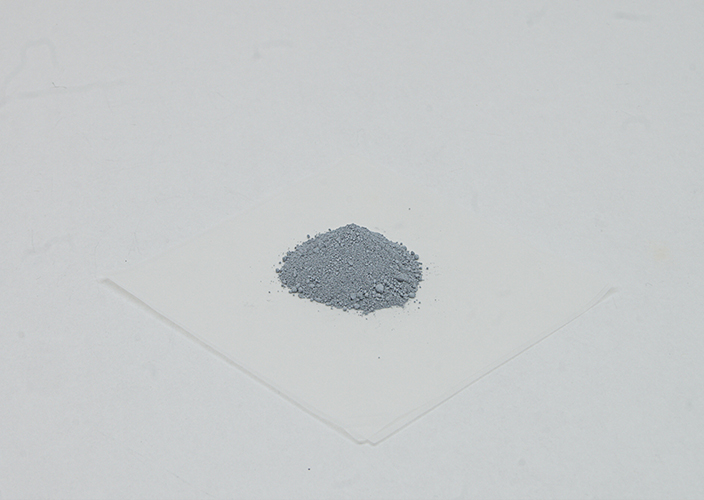

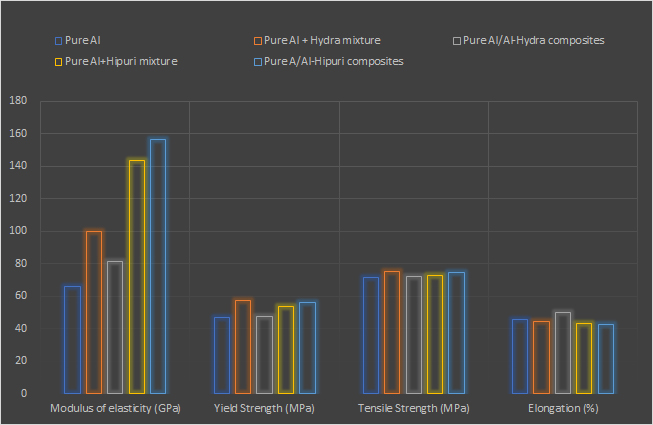

Graphene Metal Casting Materials

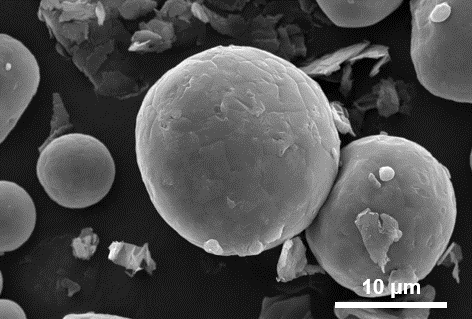

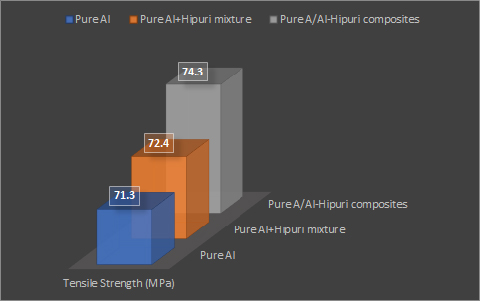

Graphene-metal alloy has been proved through numerous studies that it has superior mechanical, thermal, and electrical properties compared to conventional metal or metal alloys.

However, the density difference between graphene and metal caused separation and agglomeration between two materials during the casting process, so there was no casting material that could overcome this.

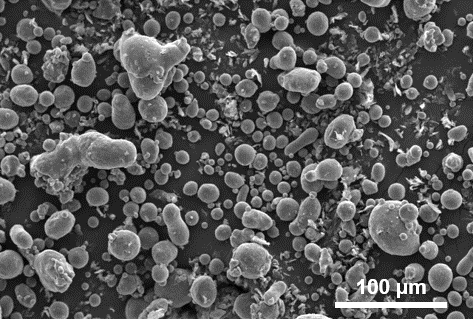

In response, we introduce Hi-puri & Hydra Al mixture/composite casting material developed based on UD's technology to suppress graphene-metal separation and form graphene-metal alloy.

Hi-puri & Hydra Al mixture/Composite castings are castings capable of mass-producing graphene-aluminum alloys and are designed to control properties by regulating the hydrogen content of aluminum alloy castings.

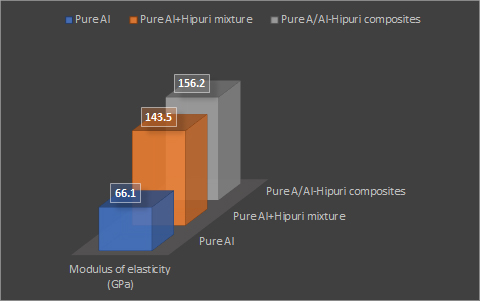

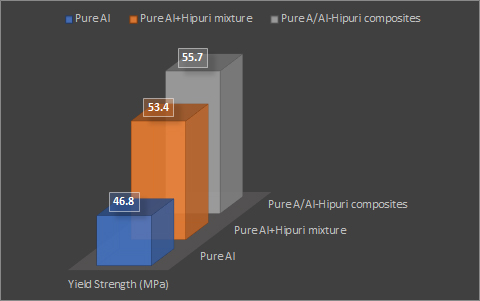

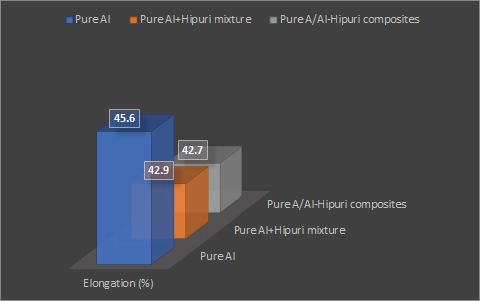

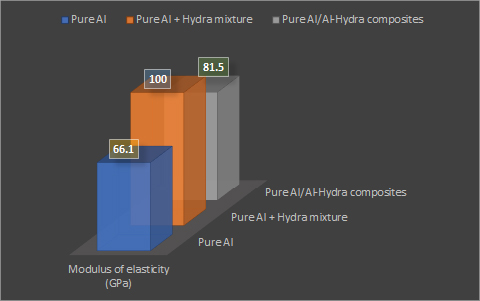

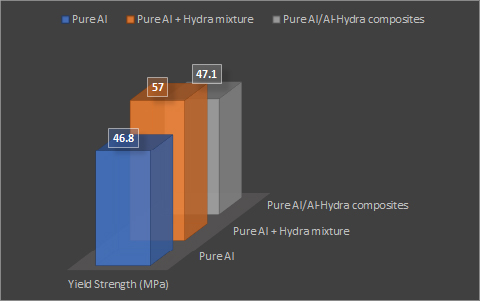

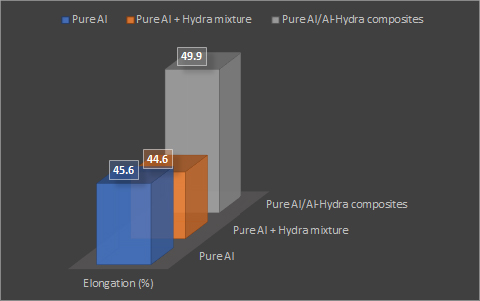

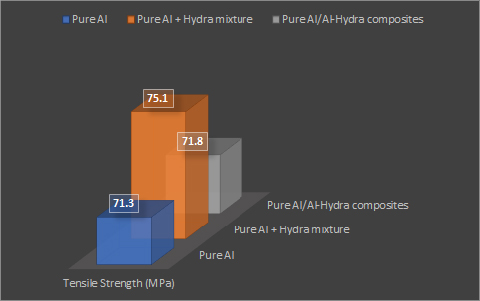

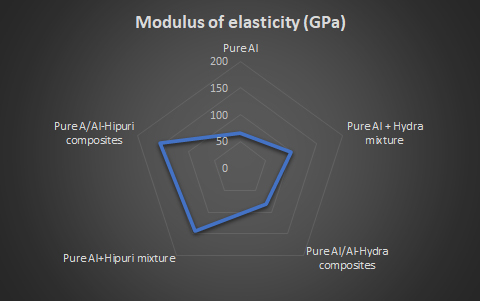

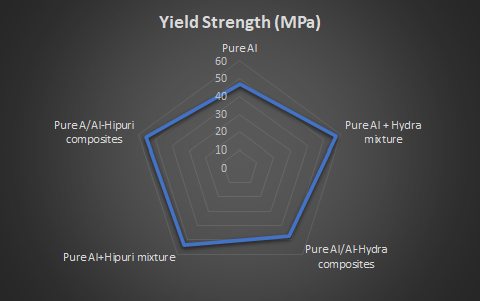

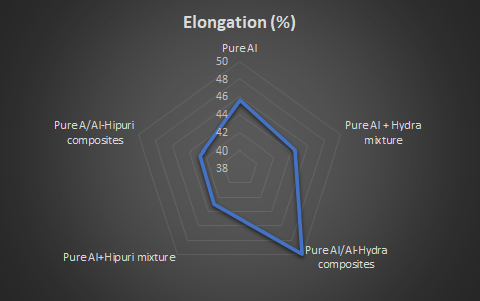

The alloy cast through UD's Hi-puri & Hydra Al mixture/composite casting material showed interesting results of 130% increase in elastic modulus, 20% increase in yield strength and 9% elongation.

This means that alloys cast from Hi-puri & Hydra Al mixture/composite tech can be expected to change a variety of industries.

In addition to being used in automotive and aviation, Hi-puri & Hydra Al mixture/composite tech are expected to be applicable to a wide range of aluminum products used in construction and everyday life.

UD's graphene metal casting technology will bring a new trend in the hybrid aluminum industry.

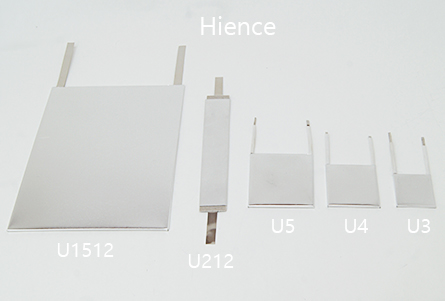

Energy Tech (Unit)

Our hybrid graphene heater is based on UD's graphene heating element manufacturing technology.

Our parts have high electrical energy efficiency (over 300%).

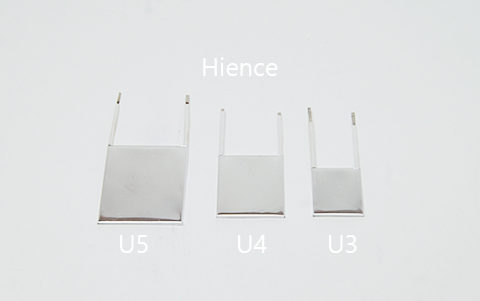

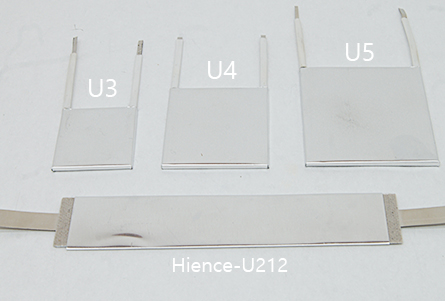

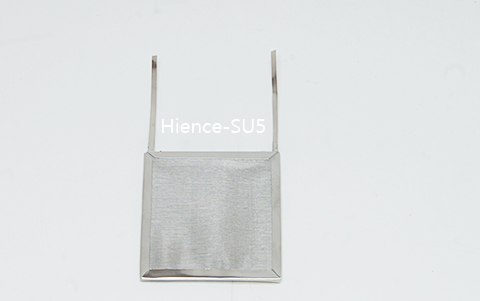

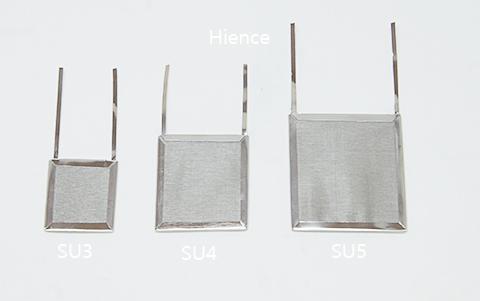

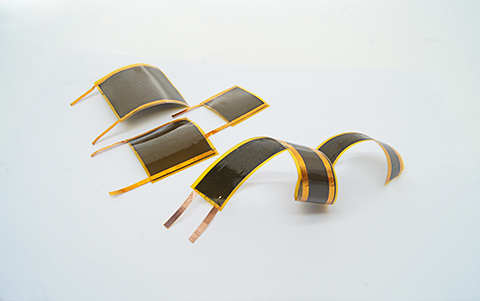

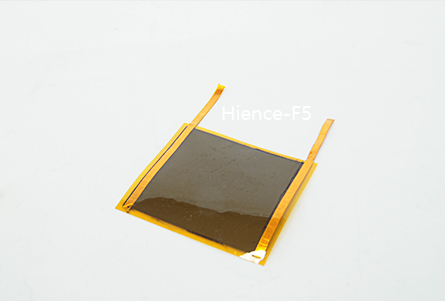

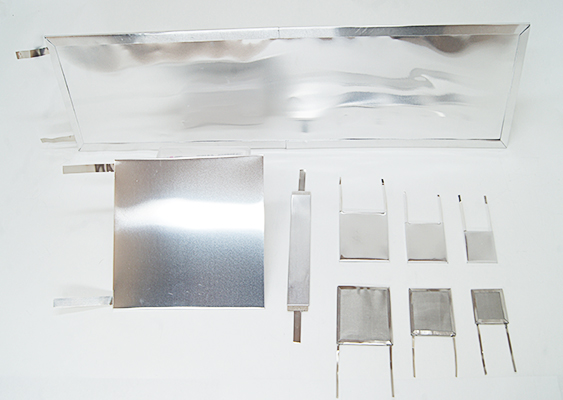

Flexible graphene heating unit : Hience-F series that show stable heating efficiency even in a bent state, and Graphene thin film heating unit :Al/Stainless covered: Hience-U/SU series, which have good temperature uniformity and have a large heating area, which is advantageous for maintaining efficiency.

They offer a wide range of temperatures from 150℃ to 600℃.

It can be applied to various places such as electric vehicles, fuel cells, electronic products, curved devices, electronic housing equipment, and industrial equipment.

This technology focuses on energy efficiency so as to reduce the burden of energy depletion and use thermal and electrical energy.

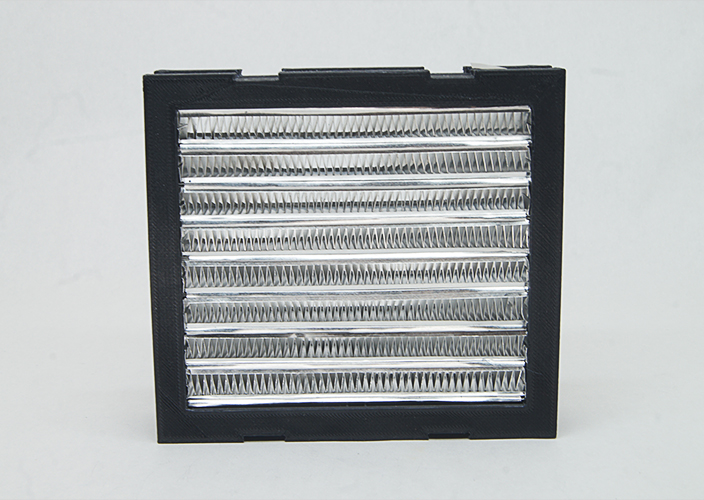

Graphene Block Heater Module

High thermal energy efficiency and reduced electric energy consumption by over 70% compared to conventional electric heaters. Block structure makes it easy to expand.